ams Digital process control with ams PILOT software

ams PILOT process control software

Benefits even for other manufacturers’ equipment

As a matter of course, ams software is being used in all amcoss wafer handling equipment for process control. It has, however, been constructed in a manner to be easily applied to control processes in other manufacturers’ equipment at any time. Therefore, the software is being reprogrammed, adjusted to the customers’ needs and transferred to the respective equipment by our experts. So, even machines with less intelligent and modern software programs may benefit from the clever and helpful options and functions of our ams PILOT.

Programmed sustainability

Sustainability is in high regard also with our ams PILOT software, because it is an important link between man and machine. All software functions and its intuitive operability are designed to fulfill the varied aspects of sustainability. So, of course, the software conforms to the latest standards and technologies. With highly precise system control it ensures smooth production processes and contributes to permanent process optimization and efficiency by e.g. increasing throughput, reducing reject and preventing breakdowns. ams PILOT enables a simple repeatability of processes and so increases the number of perfectly processed parts. With the help of comfortable maintenance functions servicability of the equipment improves and becomes more secure for the operator. Finally, amcoss software with its integrated Energy Safe Mode helps to increase energy efficiency and saves recources, that is energy and media.

Highlights

Intelligent functions for optimized processes

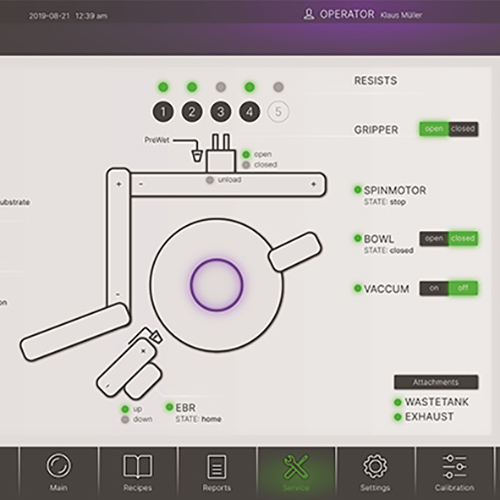

User-friendly, self-explanatory user interface

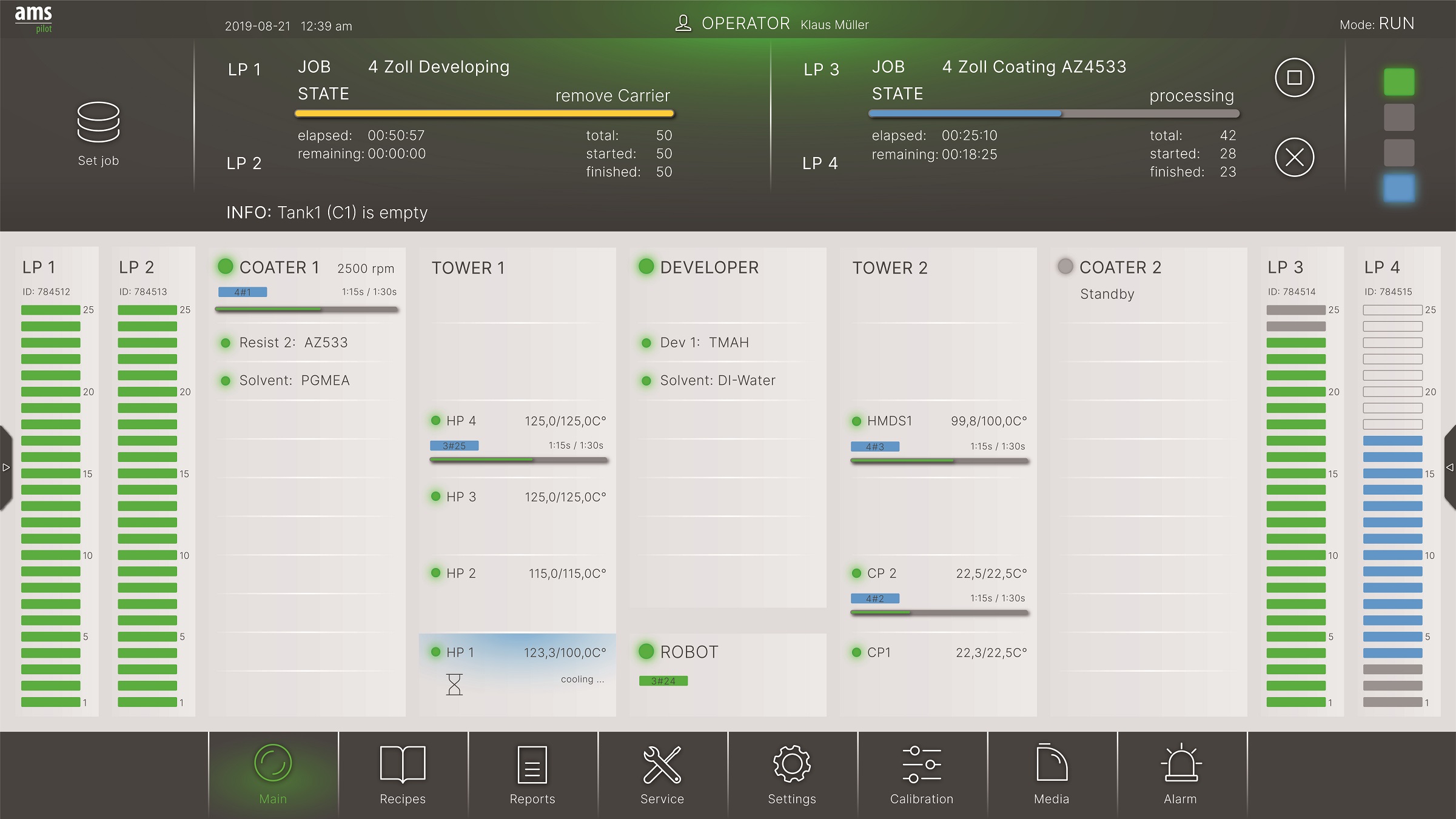

User-friendly, self-explanatory user interface

The user interface not only captivates with its modern and attractive design, but it is also very user-friendly, self-explanatory, ergonomic as well as intuitively operable for right- and left-handers likewise. Design, function, positioning and arrangement of visual and control elements comply with Semi Standard E95-1101, which harmonizes and simplifies the handling of the whole system.

Easy recipe writing

Easy recipe writing

No software programming knowledge is necessary for writing or rewriting individual recipes. Furthermore, it is possible to simply write recipes on your own PC and to afterwards transmit them to the amc or amr tool via network.

Integrated scheduling

Integrated scheduling

The scheduling function is a powerful and very precise tool for the control of the whole process cycle and the course of the individual sequences. The aim will always be an ideal process flow and maximum possible throughput. In addition, manual sequence optimization is possible, e.g. for desired delays.

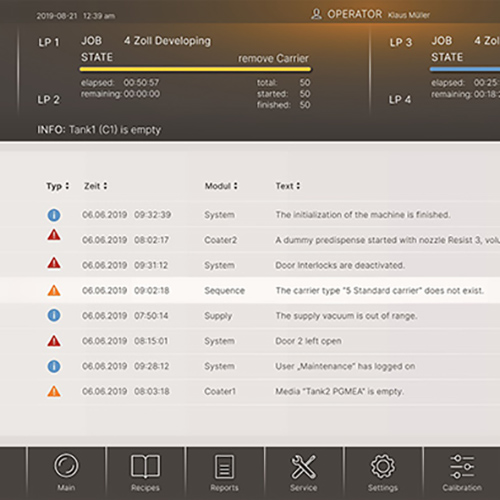

Log-function for informative reporting

Log-function for informative reporting

The integrated log file consistently generates extensive machine reports for all production lots instead of just producing simple error logs. It is possible to set lot identifications as well as individual storage modes. With only a few mouse clicks you can see actual as well as older data. All these data may be exported into standard file types.

Environment-friendly and energy costs saving

Environment-friendly and energy costs saving

With only one click, the software will reduce the power and media consumption of the whole system – which can also be controlled via timer. One other mouse click brings the tool back into operation. In combination with our intelligent media reduction during processes the customers will be able to continually reduce their energy costs.

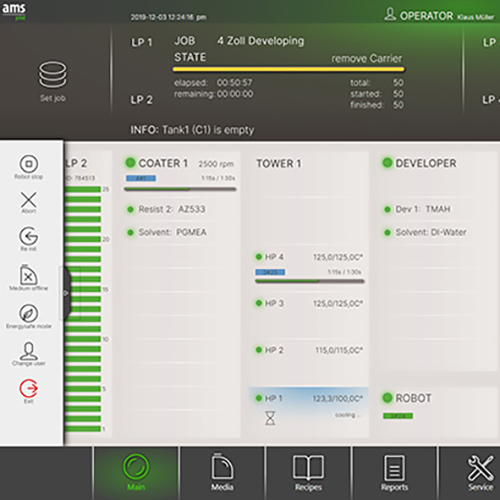

Comfortable service and maintenance functions

Comfortable service and maintenance functions

The software supports you with special service functions. So, you will easily be able to find any defective parts and components. A separate service tablet will help you to operate the software while moving around the equipment or working in another room. When you are using the tablet, the main screen will be blocked. Remote control is another important feature through which you will be able to configure, teach or service the amc tool.

Other features

Optional SECS/GEM interface

Process development

Multi-client capability