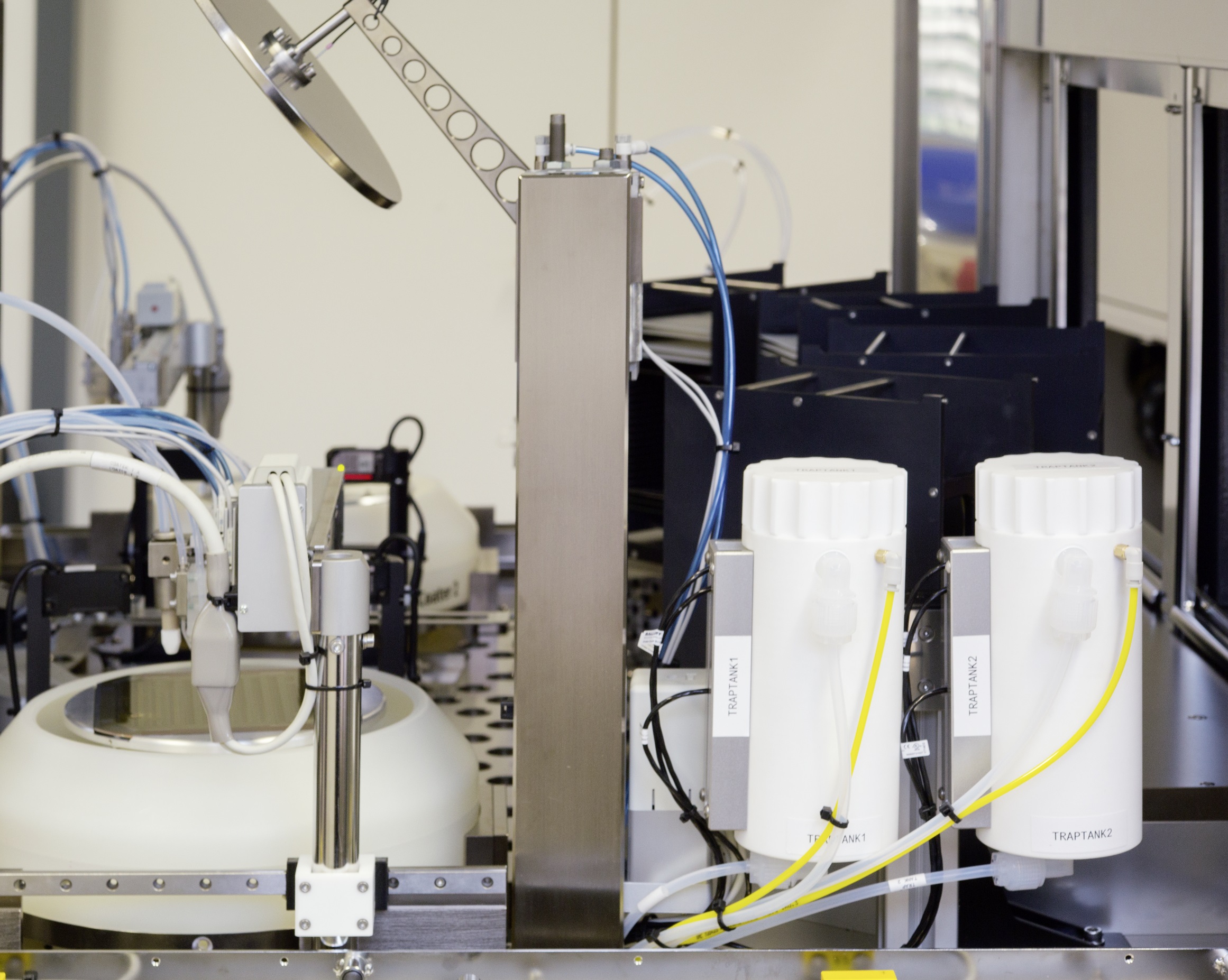

Trap Tank System

Special resists dispense system for wafer coaters

With our amcoss trap tank system we have developed a special, innovative, and efficient resist dispense system for use on our amcoss single wafer spin coating equipment, as well as for retrofits on other OEM coaters. It replaces conventional resist pumps by an air- or gas-driven tank which enables the handling of a much bigger resist reservoir and avoids bubble formation.

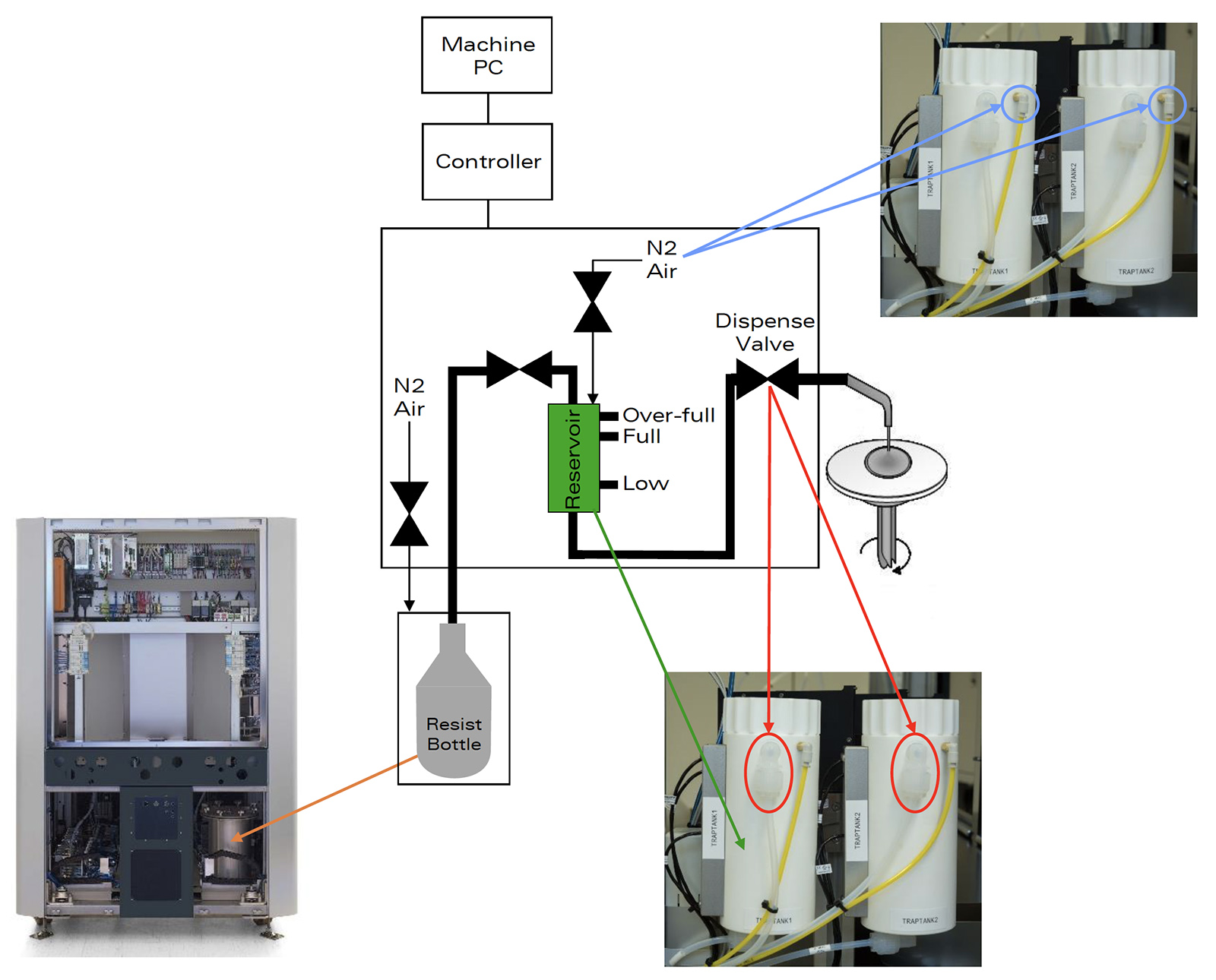

Mode of operation

The system consists of a sensor-controlled reservoir and a suck-back dispense valve. The reservoir supplies the dispense valve which is mounted near the nozzle. The resist volume is set by pressure and trigger time.

If the reservoir reaches empty level the tool can still run a predefined number of wafers. Furthermore, the tool is equipped with a sender cassette stop and the tank will be refilled automatically from the resist bottle. The over-full sensor prevents the reservoir from overflowing in case of a technical defect of the full sensor and stops automatic refilling. Thus, it guarantees maximum safety.

Technical details

- Pressure regulation 0,1 mbar

- Gas filter 0,001 µm

- Resist filter according to customers specification

- Dispense volume +/-0,1ml or 10% accordingly

Retrofits of non-amcoss tools

When retrofitting other OEM tools with our trap tank system a controller with touch panel is added to the existing equipment. The track output triggers the PLC which controls the dispense valve.

System advantages

- Easy to clean

- Customized size of reservoir (20 ml to 250 ml) enables multiple series dispense

- No waste of resist due to efficient filling procedures

- Bubble formation is avoided because resist enters at top and exits at the bottom of the trap tank

- Handling of small resist samples possible

- Exceptionally reliable, cost-efficient and low-maintenance due to a reduced number of mechanical parts

- Dispense of high viscosity resists up to 14.000 cps

- No high pressure in dispense line which avoids segregations of solvents in photoresists as well as the formation of striae and spots